BEHIND THE RENDER: WAYS TO USE POINT CLOUD DATA

BEHIND THE RENDER: WAYS TO USE POINT CLOUD DATA

Date: 9th March 2023

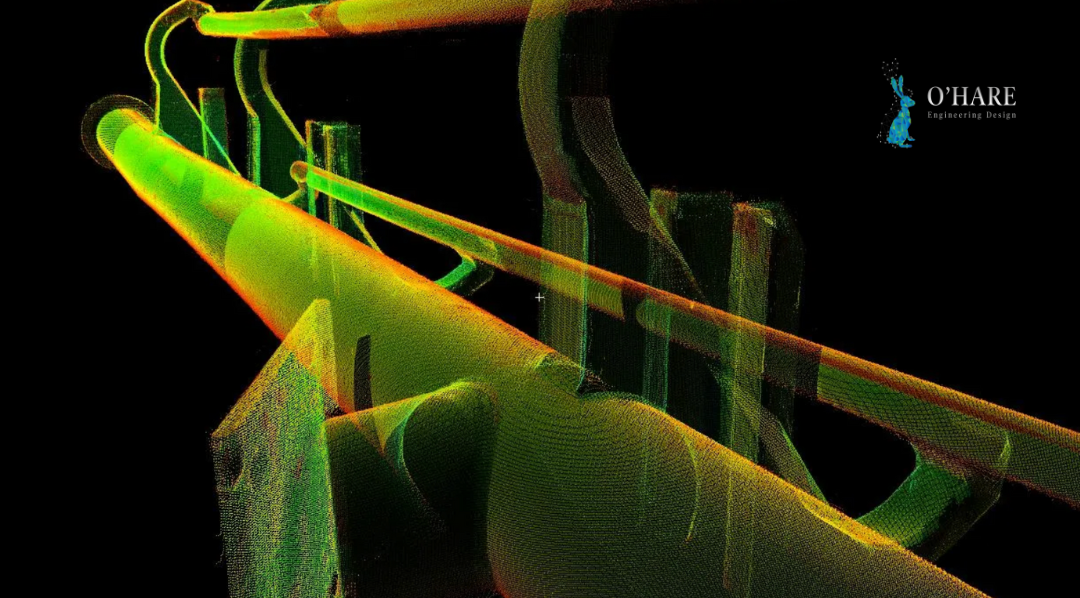

Point clouds. It's not all about building 3D models. So what actually is a point cloud? And what can you do with this data?

What is a point cloud?

When building a 3D image of a site using 3D laser scanning or a photogrammetry software, a point cloud is the point on the surface of an object or environment where your laser or software hits that's captured to create a digital copy. This point is recorded using a cartesian coordinate system, recording each point on a set of X, Y and Z axes. These are then all meshed together during the ‘registration’ phase of a scan to create your 3D image.

So, once you have this data, what are you actually supposed to do with it?

3D Modelling and Visualisations

When we’re talking about point cloud data, this is the first application most engineers will think of. This is because these points create a mesh wire frame for your chosen render to be applied. For many large-scale projects like site modelling for ‘as built’ BIM projects or complex mechanical design builds, creating these models without first having point cloud data to work from can be time consuming and affect the overall accuracy of the work produced.

Site Development and Retrofitting Projects

How many asset-based mechanical design projects, a complete 3D model and visualisation isn’t always required. What is required though, is an accurate representation of the current ‘as built’ conditions of the site so that your design engineer can be sure to work or fit exacting specifications. For many projects, highly accurate point cloud data alone can form enough of a basis to guide in the development of the site, without the additional time or cost that comes with a complete 3D model or visualisation.

This is also true of reverse engineering and retrofitting as the point cloud data allows a designer to overlay project designs over the existing infrastructure to clarify that the design is feasible.

3D Asset Tagging

An integral part of mechanical design currently is the development of business information modelling (BIM) and digital twins. A very simple version of these practices, however, is to use the point cloud data collected about a site and overlaying this on photographs and imagery that is also collected by your laser scanner to embed information about your site. This way you can build up an interactive asset management system that holds all the information and documentation about how the site and equipment functions, as well as P&IDs, manufacturer information, maintenance, and health and safety logs and links them directly to the piece of equipment or point on site they refer to..

Site Verification and Project Tracking

We all know how long some projects can take. Particularly in industries like nuclear and petrochemical, it’s not unheard of that development can take years if not decades to be completed. When this is the case, details can be missed and timescales can drag if careful project management and tracking doesn’t take place. This is where point cloud data can really come into its own and add real value to a project because it can act as a record of progress when collected at key milestones in the build. When compared to previous scans of the build, this data can be used to track changes, monitor progress and highlight any parts or components that are missing by overlaying it onto your designers drawings.

In their own rights point cloud data can be considered a real asset within your business, even before any render or model has been applied. If you’re interested in finding out more about any of these applications, please get in touch with a member of our team today at

enquires@ohare-eng.co.uk.