Contact us

Lets get your project started.

Over the past 20 years, we have worked with numerous clients in a variety of fields, enabling them to bring their vision to reality.

When you utilise us you'll be working with a team that are dedicated to you, with your best interests at heart.

Ready to take the next step in your engineering design project? Why not give us a call or drop us an email and we can arrange an informal chat..

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

We love to create and it shows.

Tell us what you have in mind

and we'll make it happen.

Blogs

Check out our latest blogs. Feel free to let us know your thoughts, we'd love to know what you think on the different subjects...

by Martin O'Hare

•

16 April 2025

Still hunting for the right drawing when something goes wrong on-site?

In high-risk environments like chemical and energy plants, delays and guesswork aren’t just frustrating – they’re expensive.

This Easter, we’re talking about:

👉Why clear, accurate P&IDs and 3D models are more than "nice-to-haves"

👉How smart drawings help your team move faster and safer

👉The true cost of outdated site data

by Martin O'Hare

•

27 March 2025

Are project approvals slowing you down?

Waiting on planning permission, regulatory sign-off, or stakeholder buy-in can feel like watching paint dry. This is especially true when outdated drawings or inaccurate measurements are the cause of these delays and revisions.

But what if you could remove the guesswork and speed things up?

In this week's blog, we’re exploring how 3D laser scanning helps achieve faster project approvals.

by Martin O'Hare

•

3 March 2025

Is 3D laser scanning worth the investment?

When making decisions for engineering projects, balancing cost, time, and quality is always a challenge.

And one of the biggest questions when investing in new technology for your project is whether the return on investment (ROI) justifies the upfront cost. Or is it just going to be additional cost and time?

The benefits of 3D laser scanning aren’t always immediately obvious, but they can be substantial. So, how can you calculate the ROI of 3D laser scanning and determine if it’s the right choice for your next project?

We’ve put together a detailed breakdown of how to measure the financial benefits of 3D laser scanning in your projects.

by Martin O'Hare

•

4 February 2025

In any engineering project, especially in complex environments like chemical plants, proper planning is everything. It’s what separates smooth, successful execution from unexpected delays, costly mistakes, and potential safety hazards. Front-End Engineering Design (FEED) studies are one of the best ways to ensure these are the case.

But what exactly happens during a FEED study, and why is it so essential in industries like chemical engineering?

by Martin O'Hare

•

12 December 2024

As Christmas draws nearer, Santa’s workshop is a hive of activity, with each elf diligently crafting, wrapping, and sorting presents to ensure everything is ready for the big night. Behind the scenes, the elves play a crucial role in bringing the holiday magic to life, but in a workshop as bustling as the one at the North Pole, there’s no room for complacency. Health and safety are just as important as holiday cheer.

With the workshop so full of activity - sharp tools, heavy packages, moving parts, and even flying reindeer - it’s clear that maintaining a safe environment is critical to keeping spirits high and accidents low. But, in a building as iconic as Santa’s workshop, how do you balance tradition with the need for up-to-date protocols?

Let’s take a closer look at how the North Pole can embrace modern health and safety practices through innovative engineering design to maintain both efficiency and the joy that defines Christmas…

by Martin O'Hare

•

27 November 2024

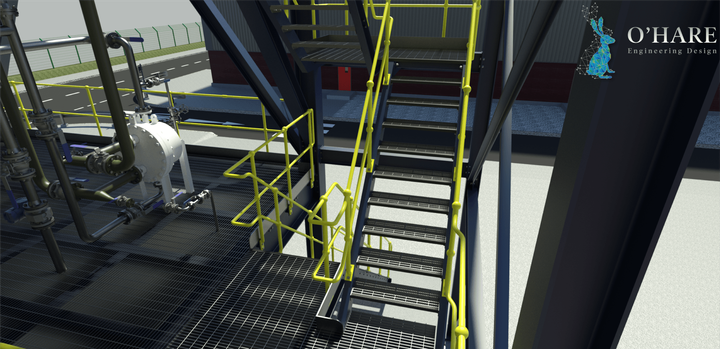

Engineering design projects, especially in chemical plants, often involve multiple teams and many moving parts. In such complex environments, ensuring everyone is aligned is critical. When miscommunication occurs, it’s often due to one culprit: inaccurate or mismatched drawings.

From high-level layouts to detailed system schematics, each type of drawing plays a unique and vital role. In this month's blog, we explore ‘The different types of engineering design drawings and what they’re used for…’

by Martin O'Hare

•

29 October 2024

When designing pipework systems that transport hazardous chemicals under high pressure and varying temperatures, safety, efficiency, and cost control are non-negotiables. Mistakes in this critical phase can lead to costly rework, operational inefficiencies, or even dangerous safety incidents.

Traditionally, piping design relied on 2D drawings and manual calculations, but as systems become more complex, so does the need for more advanced tools like 3D modelling, flow simulations, and interactive layouts. These tools allow engineers to create detailed, accurate representations of entire pipework systems, anticipating risks, streamlining installation, and ensuring the system operates correctly from day one.

So, with so many design tools at our disposal, why use visualisations in piping design for chemical plants? And how can they help optimise safety, efficiency, and cost?

by Martin O'Hare

•

2 October 2024

Chemical plants are complex industrial facilities that rely heavily on piping infrastructure to transport often hazardous materials around the site. Over time though, this infrastructure can deteriorate due to factors like age, corrosion, and general wear and tear.

Let's say this pipework is carrying something like water. If it were to fail, you not only risk flooding the site but also shutting down production until the internal problem has been resolved. Now, if you replace that with one of the more dangerous chemicals found in chemical plants, this deterioration poses significant safety and environmental risks.

To mitigate these risks, it’s important to assess the condition of ageing piping systems and implement effective mitigation measures.

In this month's blog, we’re exploring a proactive approach to pipe integrity in chemical plants.

by Martin O'Hare

•

20 August 2024

Engineering expertise is vast and varied, making it challenging to determine the right specialist for a complex project. From software to structures, there's an engineer for almost every task. But when it comes to project managing large-scale installations like carbon capture equipment, you've likely asked yourself “Do I need a Mechanical Engineer or a Design Engineer?”

by Martin O'Hare

•

19 July 2024

The UK's ambitious 2050 net-zero goals rely heavily on the chemical industry. While the industry faces challenges, exciting advancements are underway!

In this month's blog, we’re exploring the role 3D laser scanning and mechanical design are playing in Carbon Capture and Storage (CCS) implementation.